Order entry, the process of capturing and inputting customer order details into a company's order management system, inventory management systems, or ERPs, is critical in ensuring accurate and timely order fulfillment.

However, many businesses still rely on manual order entry methods, such as inputting data from paper forms or email attachments. This increases errors, processing times, and labor costs.

Nearly 67.4% of supply chain managers still use Excel spreadsheets as a management tool. This reliance on manual methods hinders efficiency and limits a business's ability to scale and meet customer demands.

In contrast, early adopters of automation have experienced a 10-15% boost in efficiency and up to a 10% increase in sales, alongside improved customer interactions and satisfaction.

Order entry automation helps solve many of these challenges using technologies like OCR, AI, and machine learning. They combine to capture and validate automatically and seamlessly input order data into relevant systems.

This article will explore pain points in existing order entry workflows and how to solve them with examples.

| Pain Point | How automated order entry solves the issue |

|---|---|

| Inconsistent order formats | Automatically extract data from any format (PDF, TIFF, JPEG, PNG, CSV, Excel, XML) and handle varying structures and layouts without templates |

| Unclear or missing order information | Validate data against predefined rules and flag issues for review |

| Siloed systems | Seamlessly integrate with legacy ERP and CRM platforms |

| Manual task routing and approval chasing | Automate routing and approval workflows based on predefined criteria |

| Data errors and corrections | Minimize errors through automated data validation and extraction |

| Inability to process orders on time | Scale operations efficiently without increasing staff |

| Difficulty in handling complex orders | Handle orders with multiple line items, special pricing, or custom configurations |

| Challenges in handling international orders | Automatically detect country of origin, apply appropriate rules, and handle currency conversions and customs documentation |

What is order entry automation?

Order entry automation is a technology that automates receiving, inputting, and processing of customer orders.

It optimizes the order-to-cash cycle, starting with order capture from various channels like email, social platforms, online stores, mobile apps, EDI, aggregators, and websites.

After a customer order is validated, the order details can be automatically exported to your integrated systems, such as CRM, ERP, inventory management, and accounting software, depending on your order management setup. Then, necessary steps like inventory allocation, invoicing, and shipping are triggered to fulfill the order.

This kind of workflow eliminates manual data entry, reducing errors and increasing efficiency. A McKinsey study indicates that automation can result in a 10-15% cost reduction and decrease order processing times from 2-3 days to 1-2 hours.

Order entry automation can benefit businesses of all sizes and industries, particularly those with high order volumes or complex order processing requirements. This includes manufacturers, distributors, wholesalers, and e-commerce companies.

Order Entry Automation ROI Calculator

Notes and assumptions (click to expand)

- This calculator provides a simplified estimate of the potential ROI from implementing Nanonets Order Entry Automation.

- The hourly rate should represent the average hourly wage of employees involved in manual order processing.

- The calculation assumes that the time saved by automating order entry will be fully reallocated to other productive tasks.

- The calculator uses Nanonets' Pro Plan pricing as a basis for comparison. Nanonets also offers a pay-as-you-go model suitable for smaller businesses or lower document volumes, with the first 500 pages free and a charge of $0.3 per page thereafter.

- The calculation assumes a consistent monthly order volume and average pages per order throughout the year.

- The actual time saved by automating order entry may vary depending on factors such as order complexity and system efficiency.

- Implementing order entry automation may require some upfront investment in terms of time and resources for setup, integration, and training.

- The calculator provides a high-level estimate and should not be relied upon as a precise financial projection.

Identifying pain points in existing order entry workflows

U.S. retail operations struggle with supply chain accuracy, averaging only 63% accuracy. While manual data entry-related problems do contribute to these inaccuracies, it is not the sole reason.

Let's explore some common pain points in order entry workflows and consider how they impact your business.

1. lnconsistent order formats and layouts

Orders arrive in various formats—Excel sheets, PDFs, and even scanned images. While data extraction is often simple, capturing orders from these multiple sources and standardizing information can be challenging. It involves tedious importing, exporting, and copy-pasting between platforms.

This manual process slows down order processing and increases the chances of errors. Misread digits or skipped lines can cause significant issues.

Consequently, your team may spend more time managing data than processing orders, leading to inefficiencies, delays, and mistakes that can impact customer satisfaction and your bottom line.

2. Unclear or missing order information

Customers may not always provide complete or clear order details. Essential information like product codes, quantities, shipping addresses, or billing details might be missing, inconsistent or ambiguous.

This forces your team to spend time chasing down missing information, often through emails or scanning multiple databases. This further delays order processing and increases the risk of miscommunication and errors. Ultimately, it can lead to incorrect orders, frustrated customers, and wasted time and resources.

3. Siloed stack

If your order entry system doesn't seamlessly integrate with your other business tools, you're likely facing a data compatibility nightmare. Manually transferring data between systems is time-consuming, error-prone, and creates information silos.

Sales Rep: Ugh, give me a sec. It's there on our Order Management System. Why isn't this stuff connected?!

Does this sound familiar? Siloed systems often lead to these frustrating back-and-forths. The lack of integration makes it difficult to get a complete picture of your business operations. It can also lead to inconsistencies in data, making it challenging to track orders, manage inventory, and provide accurate customer service.

4. Manual task routing and approval chasing

If your order process involves multiple steps, approvals, or departments, relying on manual routing and tracking can quickly become a tangled mess.

Tom (Sales Manager): It's with Inventory for the final stock check. @David (Inventory), any ETA on when this can be released?

David (Inventory): Buried in orders! 😵 I'll try to get to it before EOD.

Sarah (Sales): Ugh, okay. This is going to impact our promised delivery date.

This is what manually chasing down signatures, physically moving paperwork between departments, or constantly checking on the status of approvals often looks like. It's inefficient and prone to bottlenecks. Orders can get lost in the shuffle, leading to delays and missed deadlines.

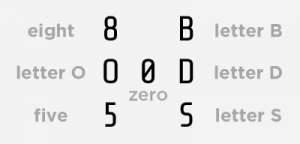

5. Data errors and corrections

Even with the best intentions, manual data entry is prone to human error. Typos, incorrect product codes, or misplaced decimals can easily slip through the cracks.

These seemingly minor errors can have a big impact. They can lead to incorrect orders, shipping mistakes, and invoicing discrepancies, resulting in customer complaints, returns, and financial losses.

Correcting these errors takes time and resources, further slowing down your order processing workflow.

6. Inability to process orders on time

Manual processes often struggle to keep up when order volumes surge due to seasonal peaks, successful promotions, or rapid growth. They don't scale quickly, requiring businesses to hire more staff or reallocate resources from other departments to handle the increased workload.

This can lead to missed deadlines, delayed shipments, and frustrated customers who are left wondering where their orders are. The inability to process orders on time can damage your reputation and ultimately cost you business.

7. Difficulty in handling complex orders

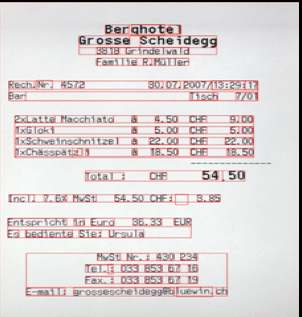

Say your team copies and pastes order details from emails into your system. But one day, you get a scanned purchase order. Your team must manually decipher the handwriting or use basic Optical Character Recognition (OCR) software to extract and input the data, potentially leading to errors and delays.

Complex orders with multiple line items, special pricing, or custom configurations can further complicate the process. Manual processes simply don’t offer the flexibility to handle these complexities efficiently.

This can result in bottlenecks, frustrated customers, and lost revenue opportunities. And employees might resort to workarounds, like online converters, which can compromise data security and integrity.

8. Challenges in handling international orders

Currency conversions, customs documentation, and shipping regulations complicate international orders. Manual processes struggle to keep up with ever-changing exchange rates and country-specific requirements.

This can lead to pricing errors, delayed shipments, and compliance issues. Additionally, language barriers may cause misunderstandings in order details, further complicating the process.

What order entry tasks can be automated?

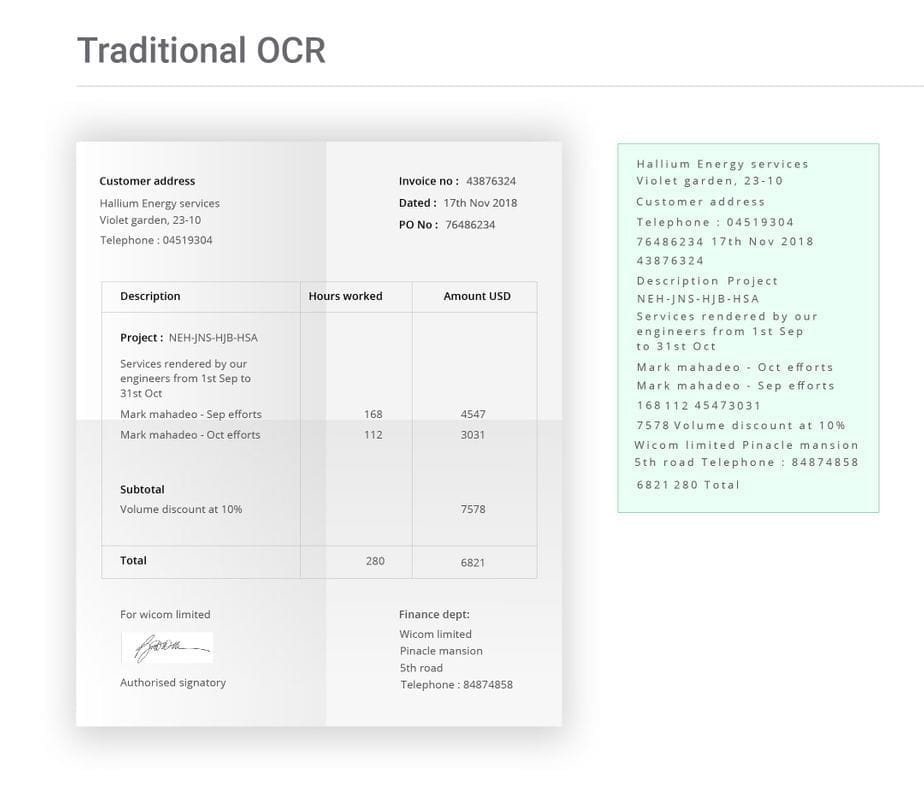

Most businesses use Enterprise Resource Planning (ERP) systems or Customer Relationship Management (CRM) software to manage larger order management processes.

However, these systems often lack advanced optical character recognition (OCR) capabilities or intelligent automation features to efficiently handle complex order entry tasks.

At the same time, companies cannot completely overhaul their existing systems overnight. This is where AI-based intelligent document processing (IDP) solutions come into play. These systems combine artificial intelligence, machine learning, and OCR, enabling them to understand, extract, and process data from various document formats.

More importantly, they can seamlessly integrate with your legacy ERP and CRM platforms, enhancing their capabilities without requiring a complete system overhaul.

Now, let’s explore some critical order entry tasks that can be automated using AI-based document processing solutions such as Nanonets:

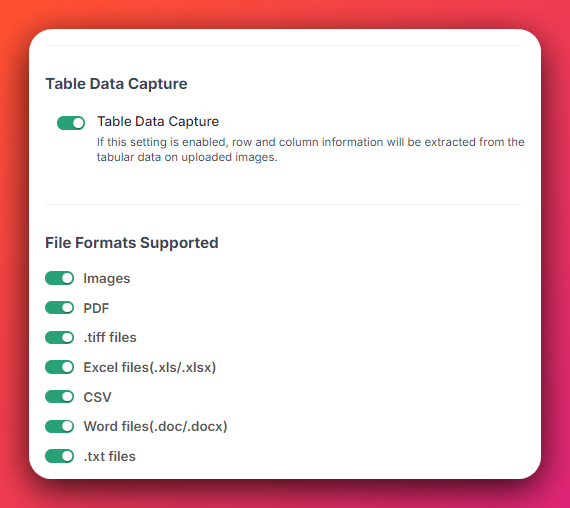

1. Capturing order data

With an IDP solution, you can automatically extract order data from any incoming format — PDF, TIFF, JPEG, PNG, or structured data formats like CSV, Excel, or XML files. No more manual data entry or import-export to different formats. AI order entry solutions leverage OCR order automation to capture data accurately.

It enables you to process everything from scanned images and PDFs to emails and even handwritten documents, accurately capturing all the critical information you need from one place.

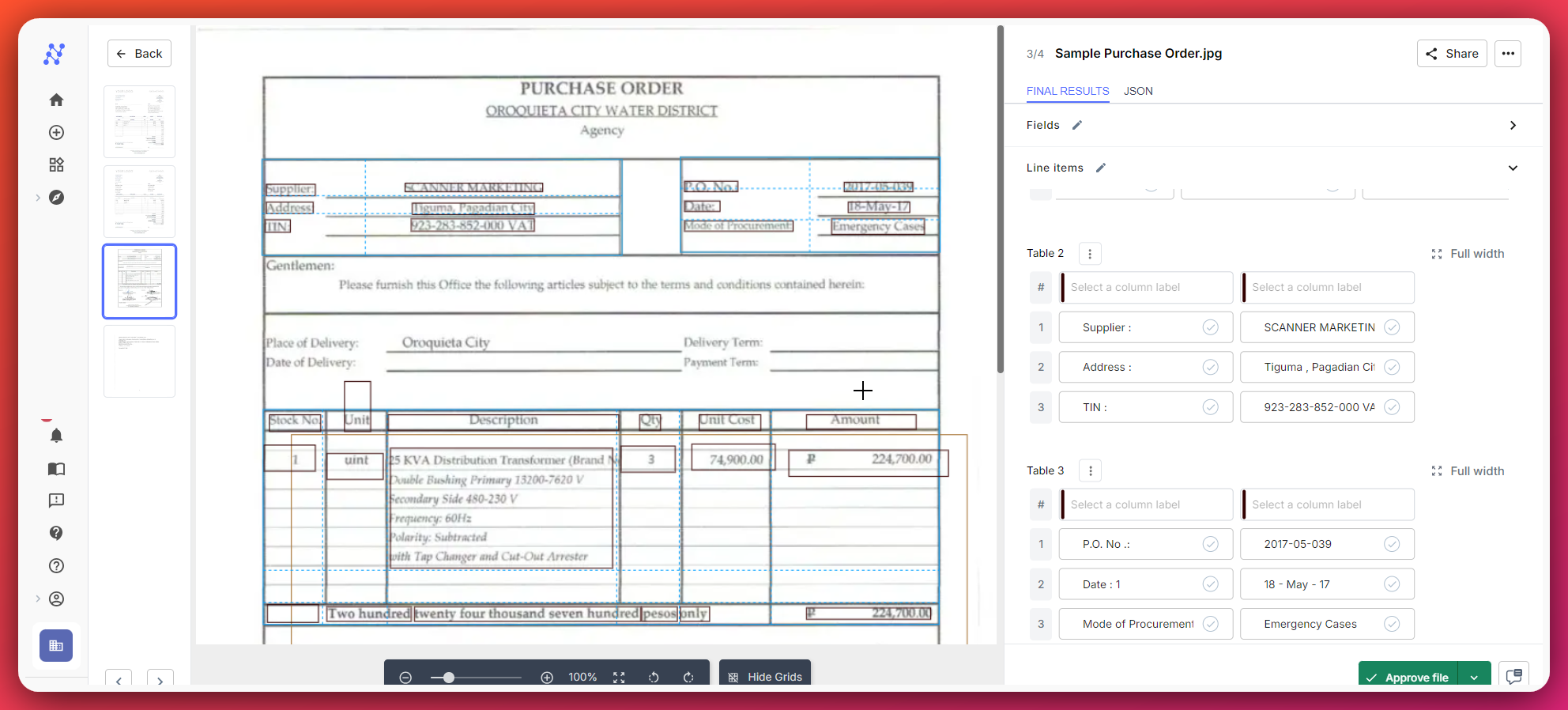

The AI and OCR capabilities of these solutions also allow you to handle orders with varying structures and layouts, such as standard purchase orders and sales orders, customer orders, line-item-based orders, and tabular orders. Even templates are not required, as the system can adapt to different document structures.

You can parse order information from scanned documents, including customer details, product SKUs, and quantities, and export it as structured information in a format compatible with your ERP or order management system.

2. Consolidating order data

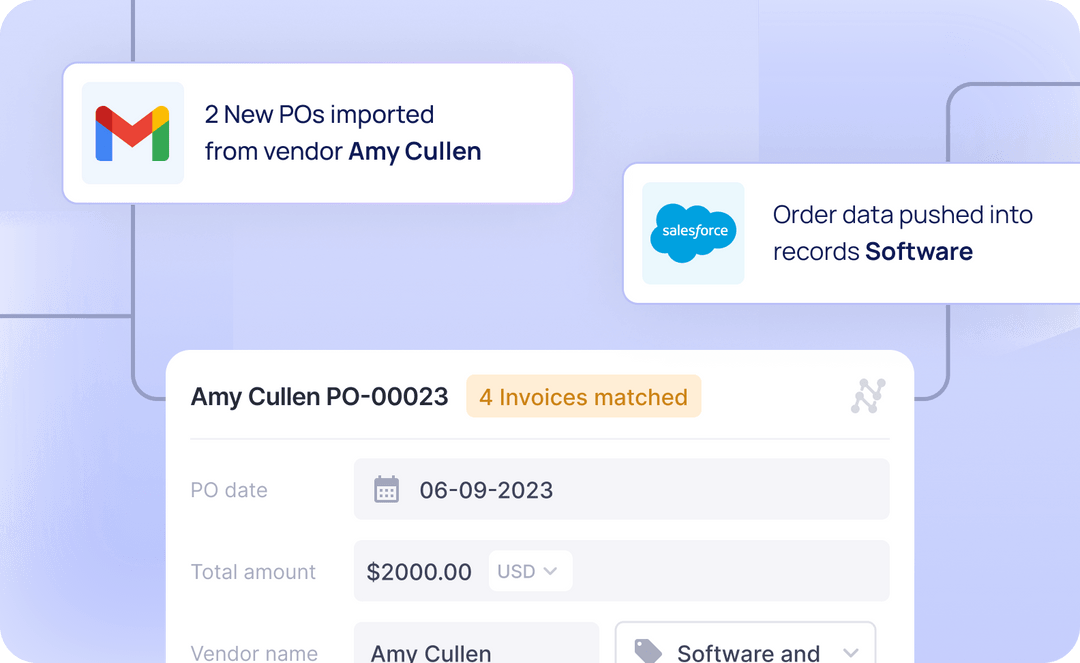

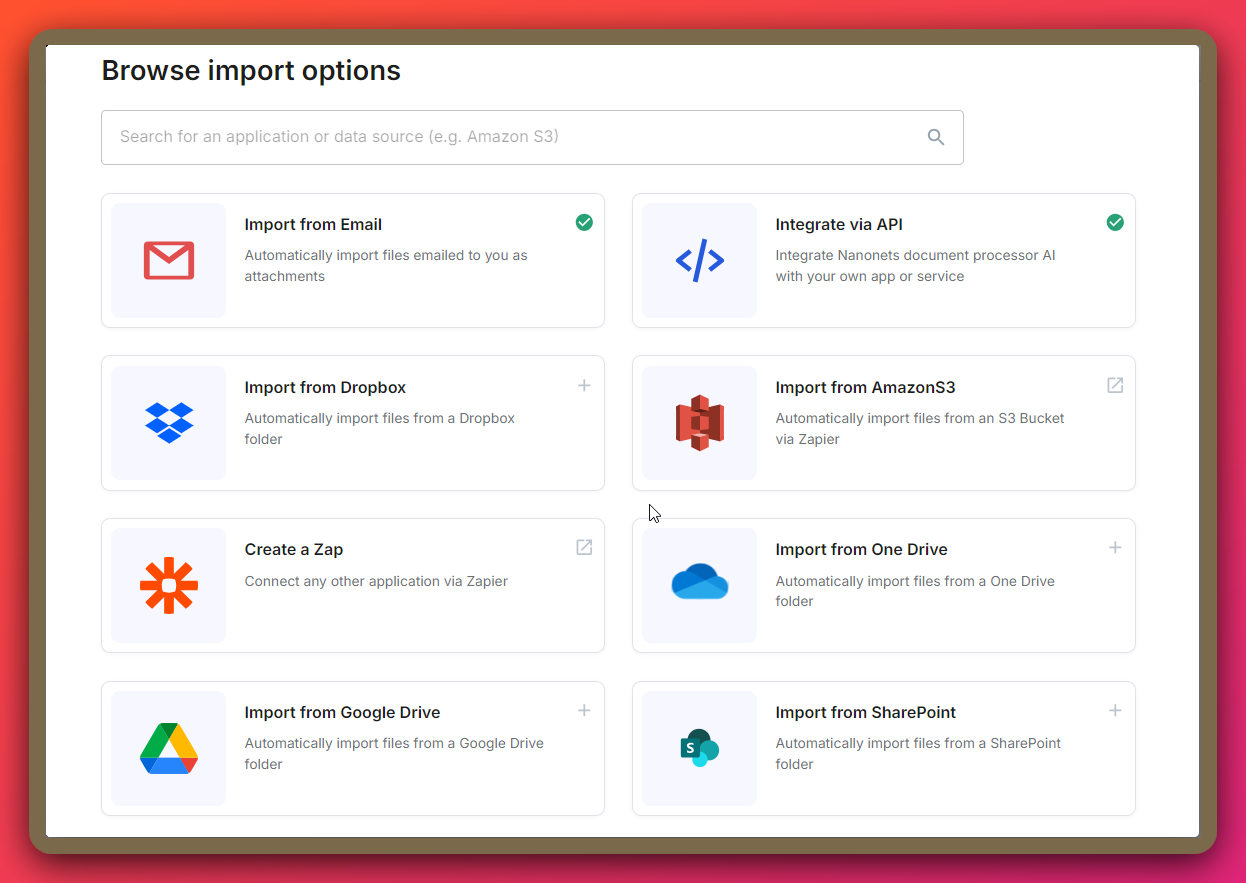

Now, with AI-powered document processing solutions, you can consolidate order data from various channels, including cloud storage, email, online forms, third-party applications, and document scanners. These tools can function as order entry systems and centralize data from all the different sources.

You can set up automated workflows to import orders from multiple sources into a centralized system. For instance, once you set up the workflow, any new email with an order attachment will automatically trigger the data extraction process.

This eliminates the need to manually log into different platforms, check for new files, and download them. The centralized system ensures that all orders are processed consistently, regardless of their origin. This streamlined approach reduces the risk of missed orders and improves overall efficiency.

3. Validating and routing order data for approval

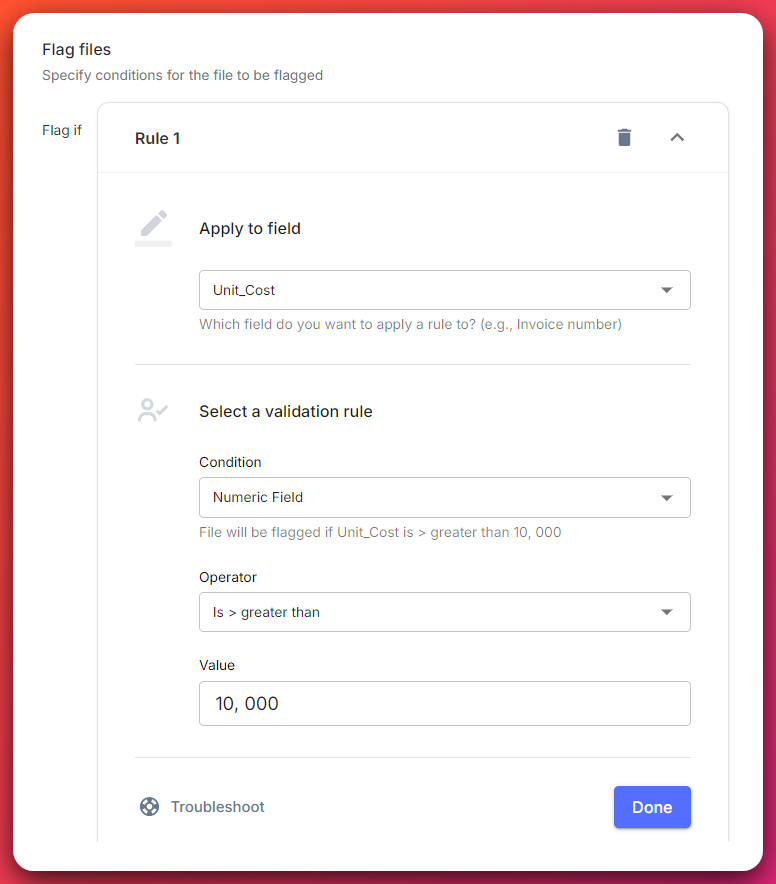

What if you could automatically validate extracted order data against predefined rules and route it for approval?

IDP solutions can do just that —check data for missing required fields, mismatched SKUs and quantities, incomplete addresses, or invalid payment information.

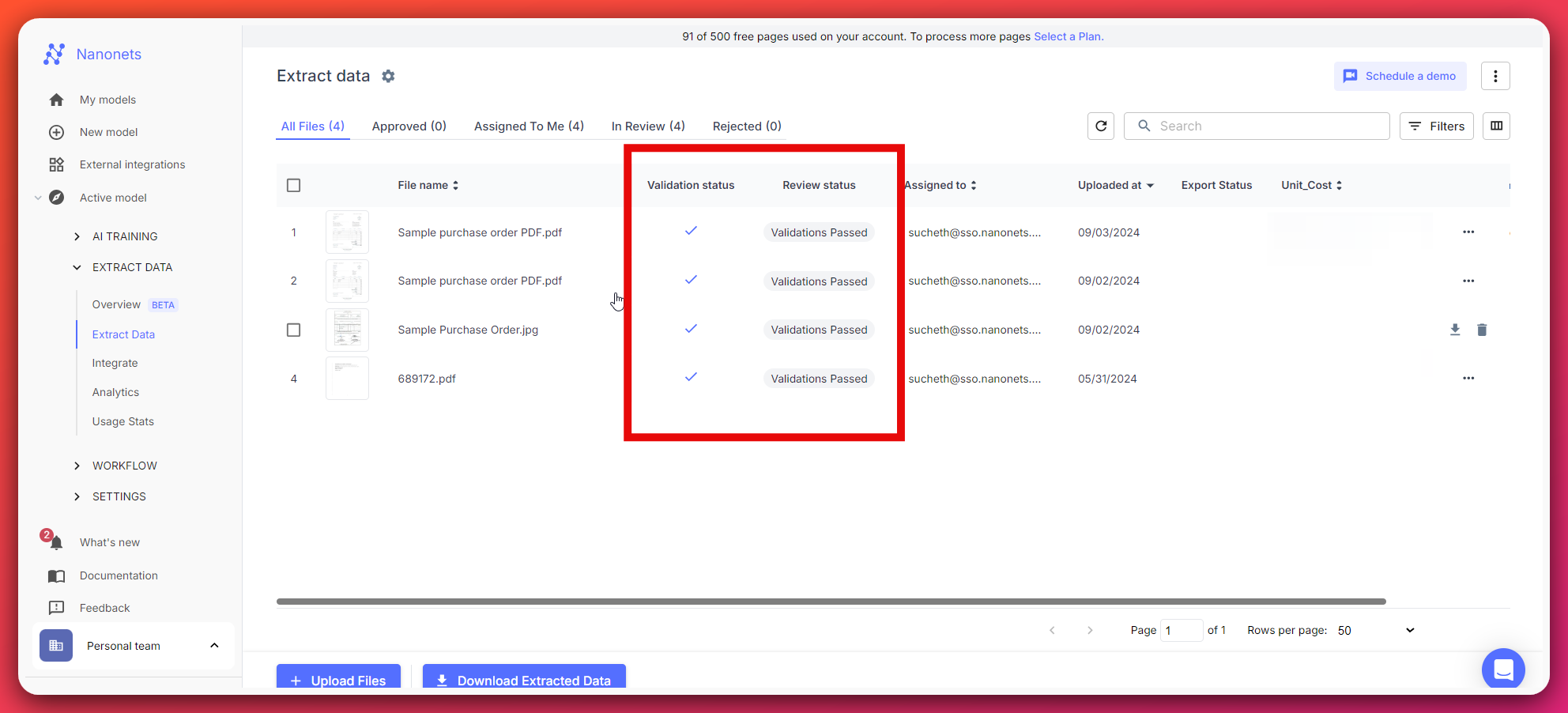

Then, order discrepancies are flagged for review and assigned to the relevant team for resolution.

This significantly reduces errors and ensures that only accurate, complete orders move forward. It also frees up your staff from tedious manual checks, allowing them to focus on tasks that actually require human judgment.

Additionally, the order automation system can be configured to automatically move on orders for approval that meet all predefined criteria, further streamlining the process.

Once validated, orders are routed to appropriate departments or personnel for approval. In case there is more than one approver, the system can manage multiple levels of approvals based on pre-set rules and escalate when necessary. This eliminates manual follow-ups, reduces delays, and ensures smooth and efficient order fulfillment.

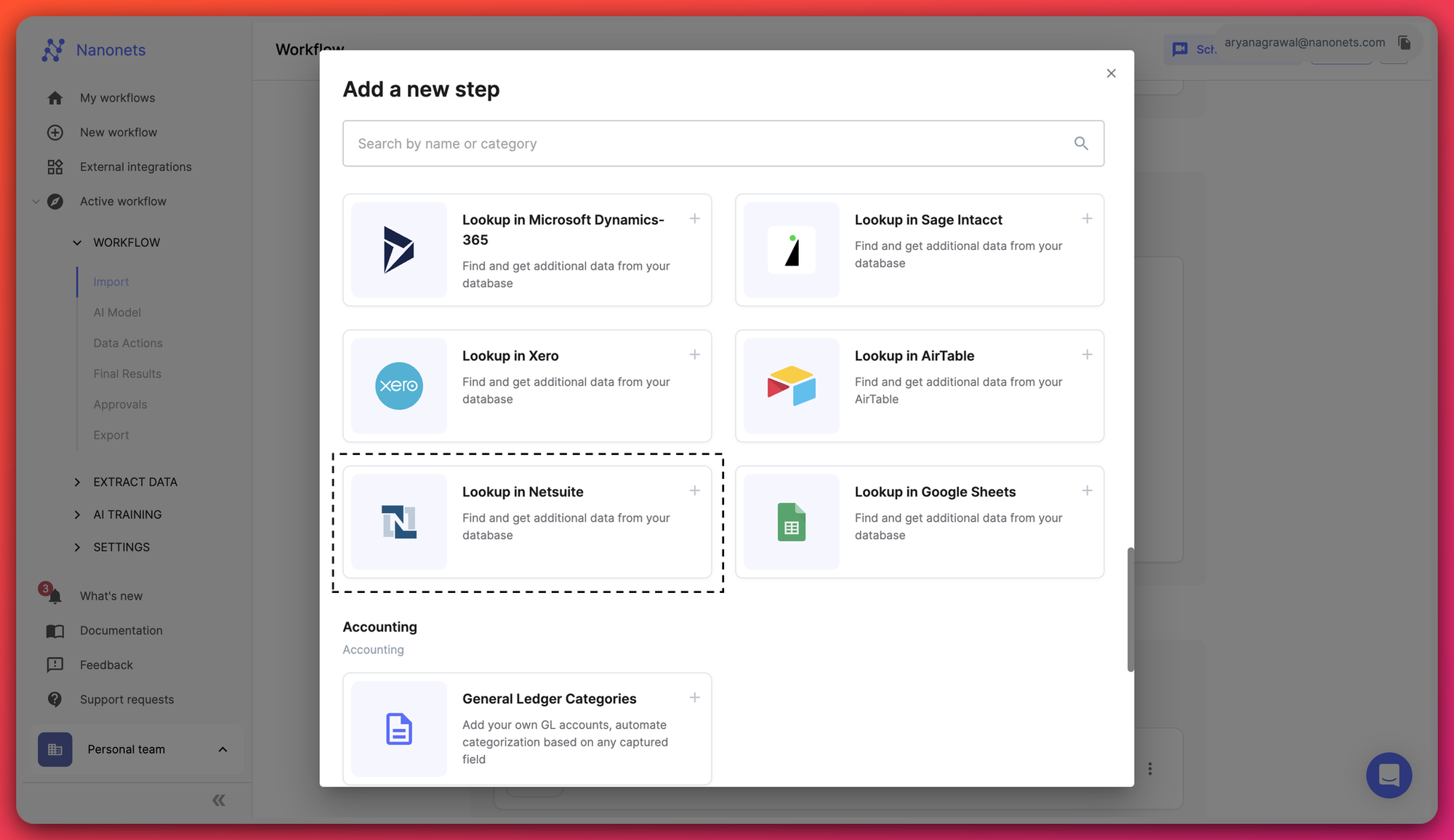

4. Enriching order data with additional information

Sometimes order data may be incomplete or require additional information from external sources. Using database matching and data enhancement, IDP solutions can automatically enrich order data with relevant information.

This might include pulling customer details from a CRM system, fetching current product pricing from an inventory database, or adding shipping rates based on destination.

Just set up data mapping and transformation rules within the IDP to match and merge the extracted data with the information from the integrated sources.

This ensures that orders are processed with the most up-to-date information, reducing the need for manual lookups. It also helps personalize the customer experience by incorporating relevant historical data or preferences.

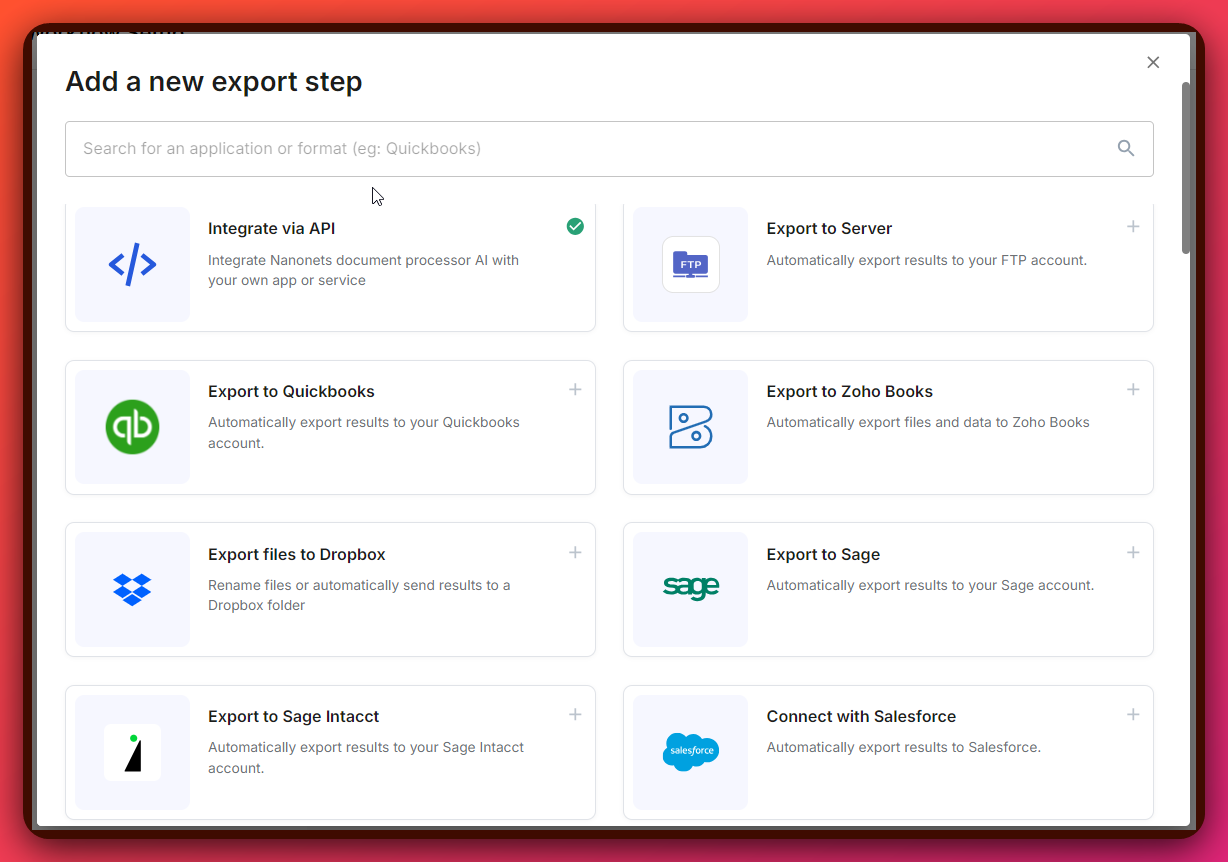

5. Synchronizing order data across business systems

As an order moves through your system, all relevant departments and stakeholders must have access to up-to-date information.

IDP solutions typically offer robust integration capabilities, allowing real-time data flow and synchronization. With native APIs or third-party integration like Zapier, you can seamlessly connect your IDP solution with your ERP, CRM, and other business systems.

Even when there are changes or updates to the order, these can be automatically reflected across all connected systems.

This level of integration ensures that all departments have access to the same accurate information, reducing miscommunication and improving overall operational efficiency.

It also enables real-time order status tracking, allowing customer service representatives to provide timely updates to clients without requiring manual inquiries.

6. Prioritizing and routing orders based on predefined criteria

Sometimes, you may need to process high-priority orders faster. It could be due to customer requests, VIP clients, or time-sensitive products. Automated order prioritization can help streamline this process.

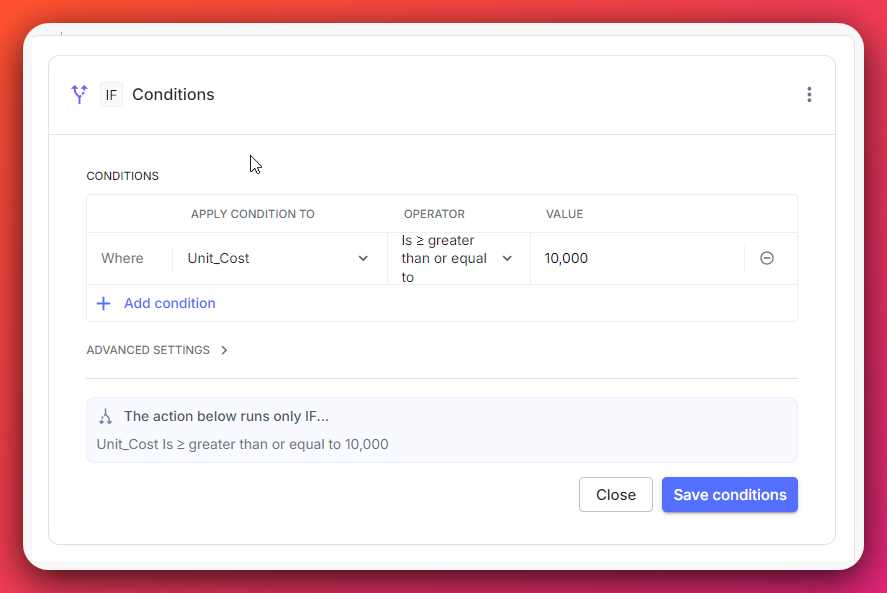

In the IDP solution, use conditional blocks to set up rules like if the unit_cost extracted on a document is higher than a certain amount, then set the priority_field to "high".

This should be reflected in the extracted data. Then, use workflow automation to assign them to specific team members. This ensures faster processing and fulfillment of these critical orders.

7. Processing international orders with country-specific requirements

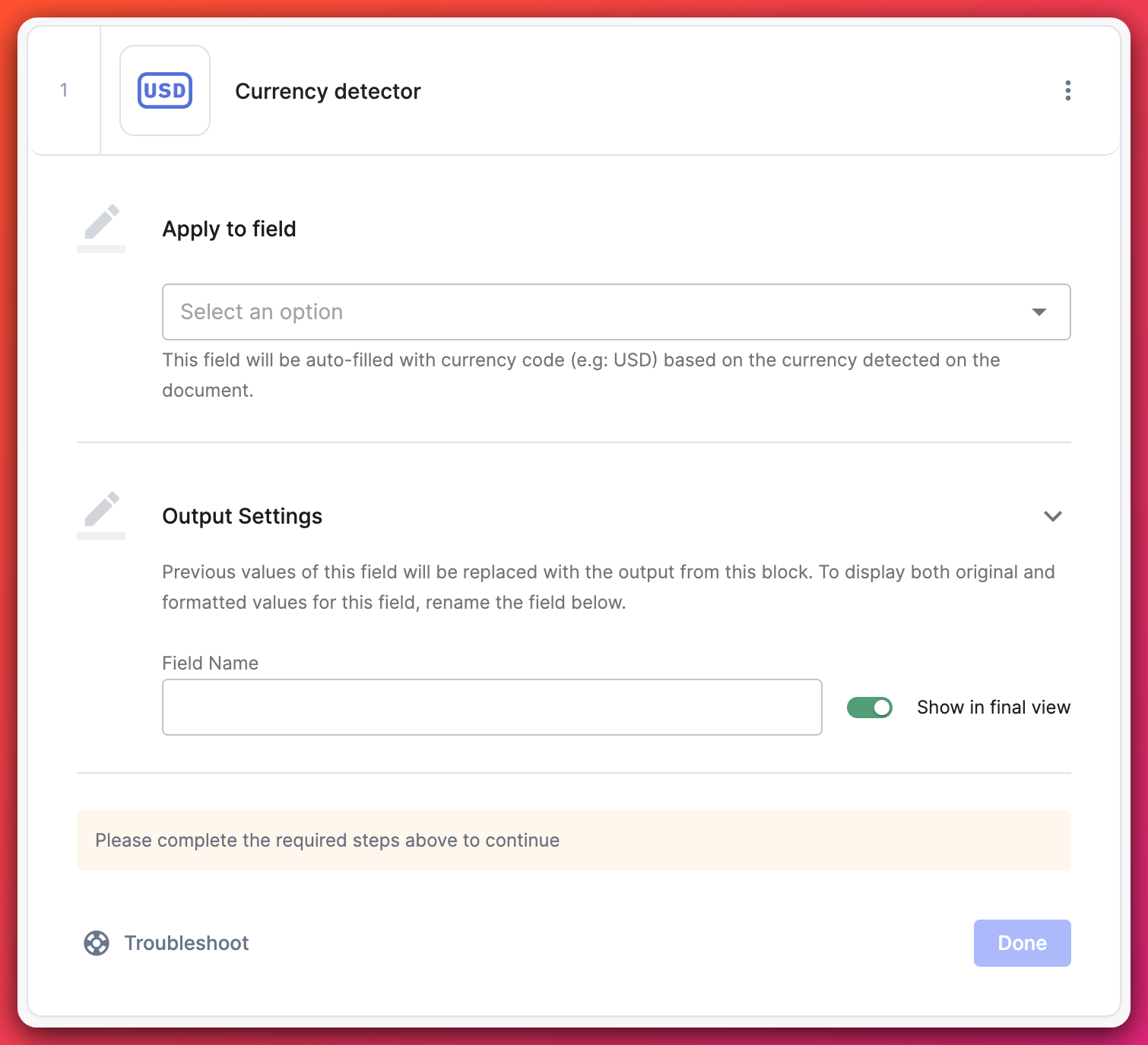

International orders often require additional processing steps, such as currency conversion, customs documentation, and compliance with local regulations. IDP solutions can automatically detect the order's country of origin and apply the appropriate rules and workflows.

This includes converting prices to the correct currency, generating necessary customs forms, and ensuring compliance with international shipping regulations.

Moreover, it can help you overcome the language barrier by translating order details into the required language for processing. This automation significantly reduces the complexity of handling international orders, minimizing errors, and ensuring compliance with global trade regulations.

8. Creating sales orders in ERP systems

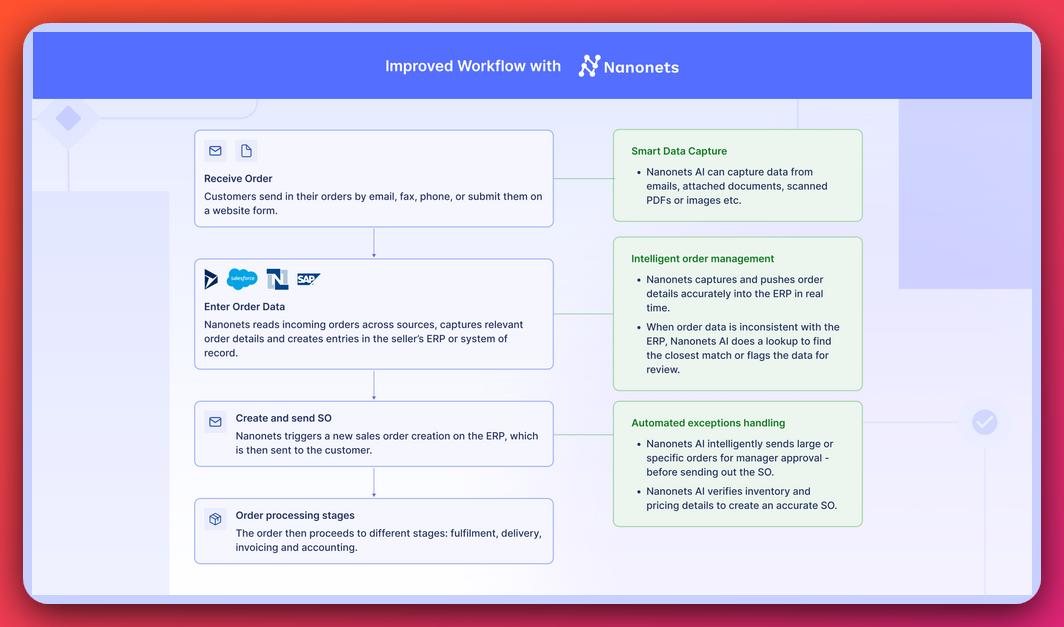

Sellers often use sales orders internally to track orders and manage inventory effectively. Sales Order Automation using IDP solutions can streamline the entire sales order creation process, from capturing order data to generating the final document.

These AI-powered order entry systems simplify the entire sales order process. They start by classifying incoming purchase orders and then extract the essential information. The extracted data is validated against master data, identifying inconsistencies or missing information, and custom validation rules and approval workflows can be set up.

Once validated and approved, IDP pushes the data into your ERP system via API, directly creating sales order requests or sales orders. This integration saves time and effort, allowing your team to focus on more strategic tasks.

IDP can also attach supporting documents to the sales order in ERP, enhancing traceability and providing a complete reference.

Final thoughts

Traditional manual order entry processes are often riddled with inefficiencies, mistakes, and delays, which can impede business growth and negatively impact customer satisfaction. However, intelligent automation solutions provide a robust alternative by harnessing the power of AI, ML, and OCR to automate data capture, validation, and integration with existing systems.

Since 50% of order management tasks are highly automatable, implementing an IDP solution empowers businesses to minimize errors, boost accuracy, and scale their operations efficiently. Embracing IDP technology is essential for organizations looking to streamline their order management workflow, elevate the customer experience, and maintain a competitive edge.