Summary: Unlock hidden value in your O2C with automated order processing—reduce errors, save time, and improve customer experiences. Start optimizing now!

Whether running a B2B or B2C business, streamlining your order-to-cash (O2C) process can mean the difference between success and stagnation. A recent McKinsey study revealed that a shocking 3-5% of EBITDA often slips through cracks in the O2C process. That's cash you could be pocketing! Moreover, manual methods simply can't keep up with the experiences that modern customers now expect.

Automated order processing is the solution. It harnesses AI, OCR, and automated workflows to handle orders accurately and efficiently. By automating, you ensure real-time updates and error-free transactions, meeting today's demand for immediate and reliable service.

This guide will help you embrace automation to bolster your bottom line and elevate the customer experience. Read on as we explore what automated order processing involves, how it differs from traditional methods, and provide practical tips for implementation.

What is automated order processing?

Automated order processing (AOP) transforms how customer orders are processed—replacing manual tasks with a digital system that enhances speed and precision. This intelligent system streamlines the entire process, from order capture details and verifying their accuracy to checking inventory and managing shipments, all while reducing the need for human intervention.

Advanced technologies drive AOP, ensuring the seamless execution of tasks. OCR digitizes information from paper-based or electronic orders, making it actionable. AI and ML analyze this data to recognize patterns, learn from previous actions, and make intelligent choices like directing orders to the right approver or identifying potential fraud.

The system's automated workflows and integrations unite different platforms, allowing data to move effortlessly through each order processing stage. This is a stark contrast to the outdated manual methods of phone calls, paper records, and tedious data entries, which are prone to errors and delays. With AOP, businesses can handle more orders, make fewer mistakes, and provide better customer experiences.

How does automated order processing work?

On average, organizations have achieved $6 in return for every $1 invested in automating their O2C processes. Typically, the process begins with an order being placed digitally and ends with the successful delivery and payment for the product or service.

There are two approaches to automation. One is to adopt a comprehensive tool that manages the entire journey, and the other is to build a tech stack of specialized software for different phases. Both aim to improve the speed and accuracy of order processing, transforming order management.

Now, let's explore the step-by-step journey of automated order processing and how each approach enhances the stages from initial capture to final dispatch.

Digital order entry:

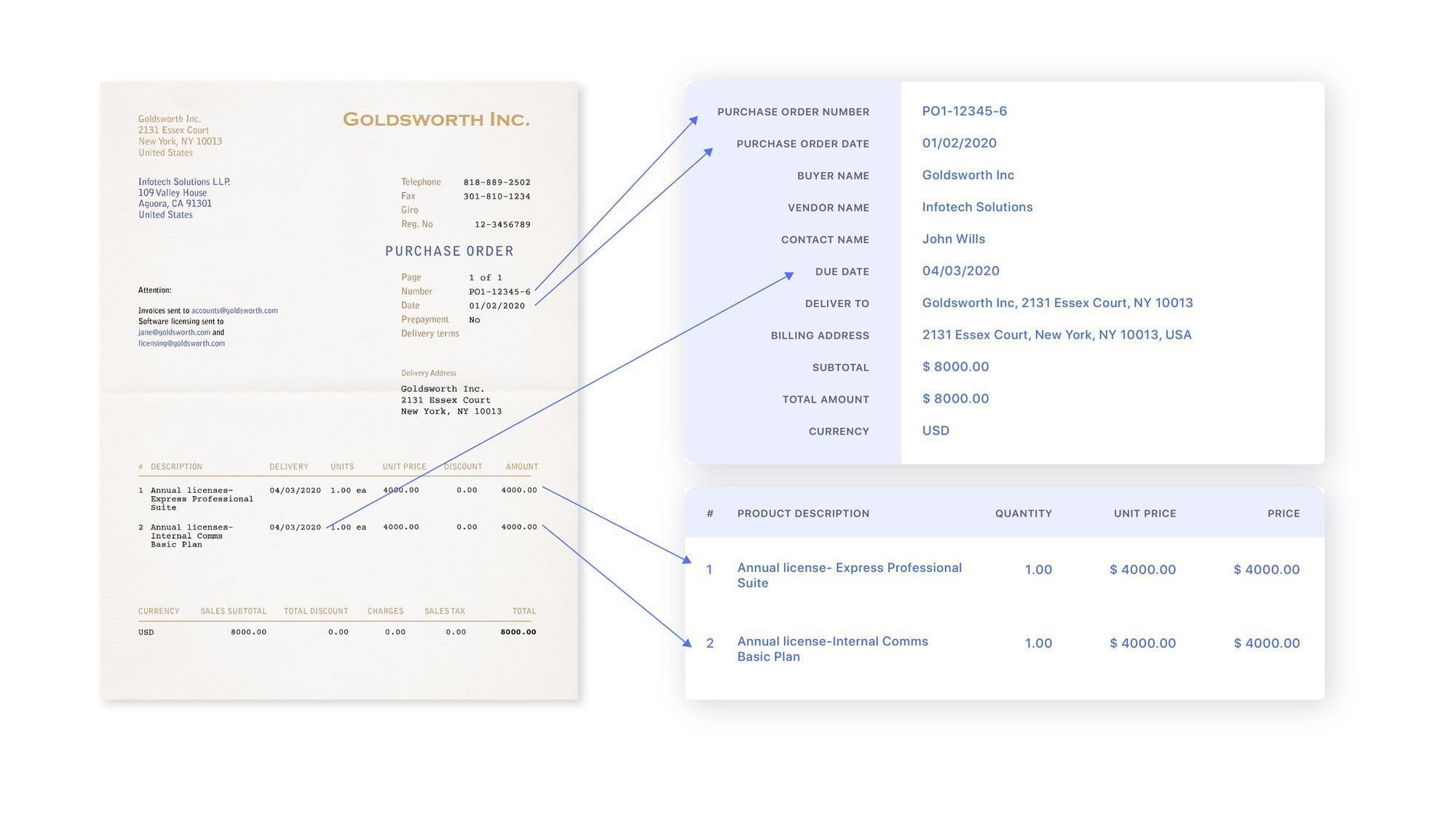

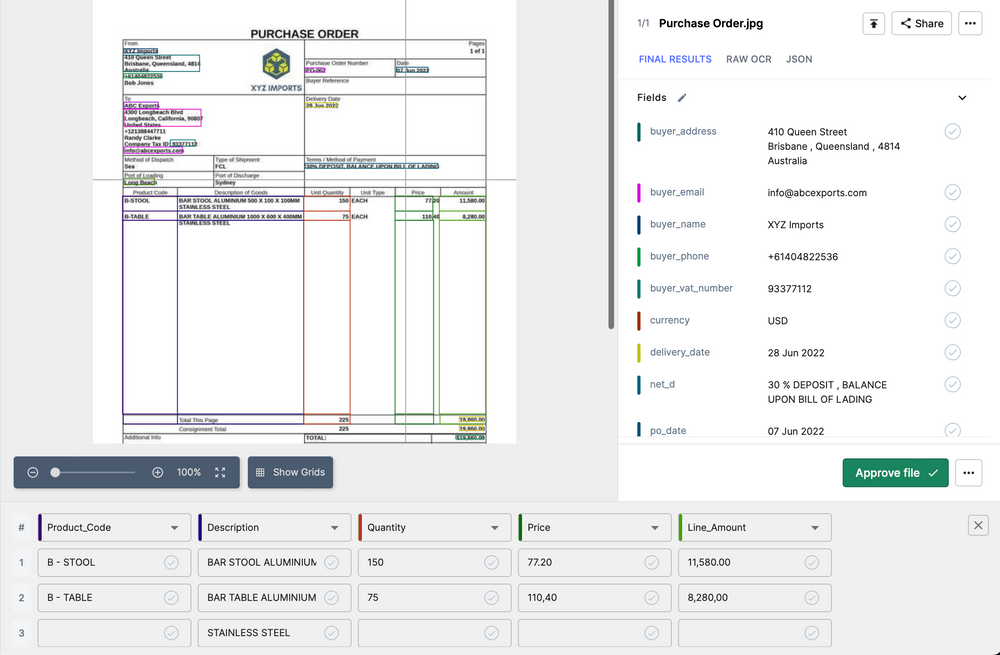

Order initiation involves capturing order details, which traditionally require manual data entry and pose risks of human error. However, OCR platform can extract order details directly from e-commerce platforms and other channels. It swiftly digitizes data from different media and logs orders into the system through order entry automation, eliminating the need for manual input. This reduces the likelihood of errors and speeds up the entire process.

Automation tools use OCR to scan and interpret information from emails, PDFs, or online forms, accurately extracting the necessary details without manual intervention. This immediate data capture further streamlines the entry phase. Additionally, APIs and integrations allow you to import order data from email directly, Google Drive, Dropbox, or other cloud storage services into your order management system (OMS).

Order validation and approval:

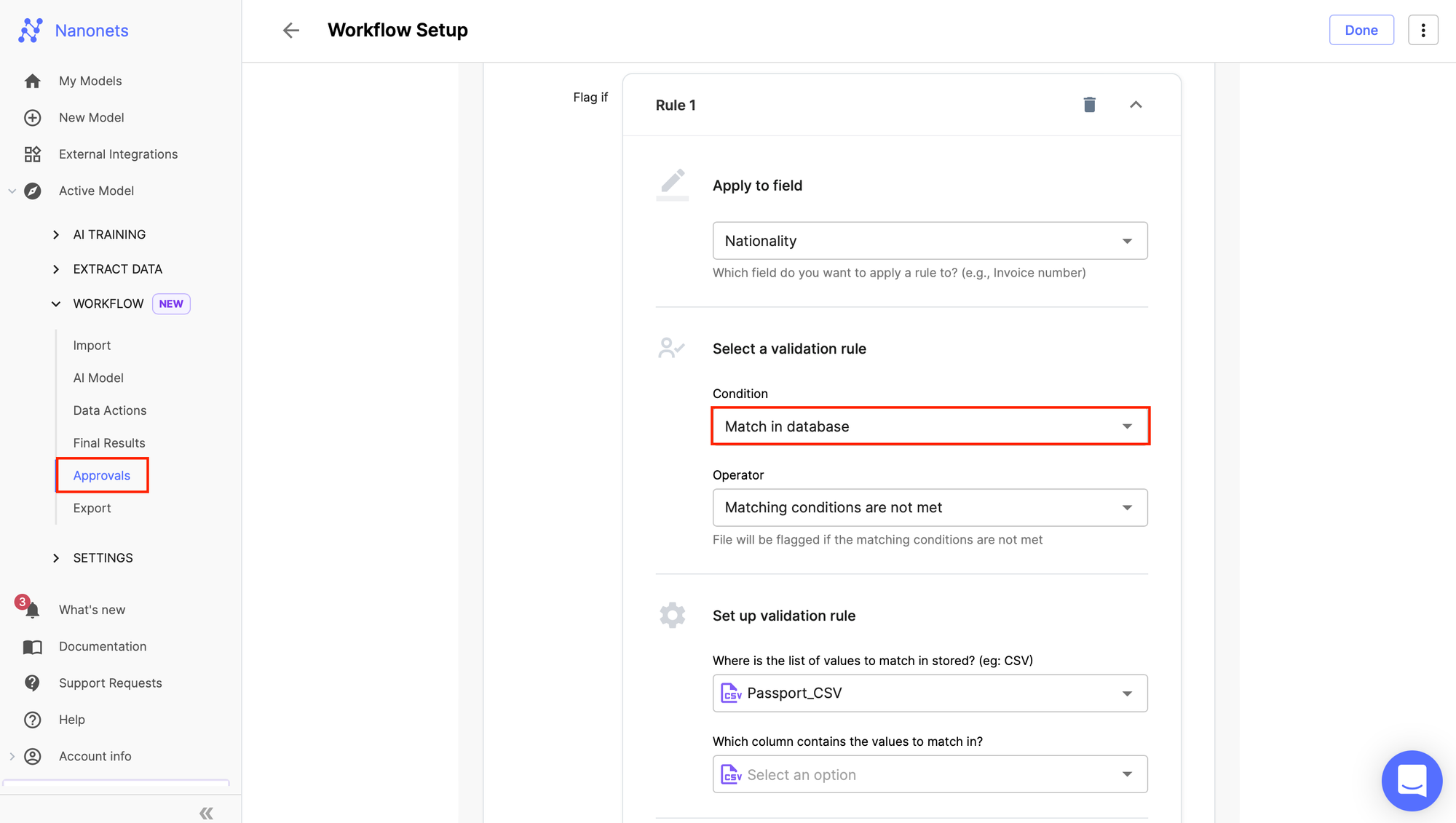

The captured order details are validated based on predefined criteria such as pricing, discounts, inventory availability, and customer credit limits. AI-driven tools can quickly compare the information against your database to confirm the accuracy and check for order discrepancies. If discrepancies arise, the system flags them for human review or returns them to the customer for confirmation.

Automated systems often come with configurable approval workflows. You can set up custom hierarchies and routing rules to automatically forward orders to the right personnel. With live status, automated notifications, and reminders, approvers can stay on top of pending tasks, thereby reducing the time it takes to move orders to the next stage. These workflows help in maintaining control and oversight without slowing down the process.

Inventory check:

The automated system will confirm if the inventory levels are sufficient to fulfill the order. It cross-checks the requested items against the current stock. This is crucial to prevent backorders or delays that negatively impact customer satisfaction. Through Sales Order Automation, the system automatically generates a sales order, invoice, or any necessary documentation to begin the fulfillment process once the inventory check is successful.

Inventory management software and the automated order processing system work together to monitor and update stock levels. It prevents the sale of unavailable items and supports better inventory planning and forecasting. Alerts for low stock levels facilitate proactive replenishment. Also, tight integration across platforms ensures the order moves smoothly into fulfillment without any hitches, helping you meet the promised delivery timelines.

Fulfillment and shipping:

Once the sales order is created, the AOP system interacts with fulfillment services to pick, pack, and prepare the order for shipping. The system selects the best shipping method based on pre-set criteria, such as delivery time frames and lowest cost. It then generates shipping labels and dispatch notes and updates the inventory accordingly.

Real-time tracking information is available both for the business and the customer, allowing for transparency and better customer service. The system automates the update of shipping statuses and sends alerts or updates directly to the customer's preferred communication channel.

Finalizing the order and after-sale service:

After delivery, the AOP system tracks the order and requests feedback. It also handles returns and exchanges according to the company's policies. This process is essential for maintaining customer satisfaction and loyalty.

The system efficiently closes the order cycle by processing payments, issuing invoices, and reconciling transactions. It captures data that can be analyzed to improve order processing and customer service strategies. These insights enable companies to be more dynamic and responsive to market changes and customer needs.

Pinpointing the pain points: where automation fits in

Every step in the order-to-cash process has potential obstacles that can delay fulfillment and impact customer satisfaction. Identifying these bottlenecks is essential for developing targeted automation strategies and delivering best customer experience.

Let’s look at possible bottlenecks and how automation could address them:

| Challenges in traditional order processing | How automation contributes to the solution |

|---|---|

| Backlogged order entries | Automation with advanced OCR technology streamlines order data capture, reducing entry times and backlogs. |

| Stock level discrepancies | Automated inventory systems provide real-time stock updates, ensuring accurate inventory management. |

| Error-prone order validation | AI-driven validation enhances accuracy in order details, minimizing fulfillment errors. |

| Shipping and dispatch errors | Intelligent routing algorithms improve shipping efficiency, decreasing errors in dispatch. |

| Time-intensive invoicing | Automated invoicing speeds up the billing process, improving cash flow. |

| Manual payment processing | Automated payment gateways facilitate faster and more accurate transaction processing. |

| Laborious returns handling | Automation simplifies the returns process, making it more efficient and customer-friendly. |

| Gaps in customer updates | Real-time, automated notifications keep customers well-informed about their order status. |

Setting up automated order processing with Nanonets

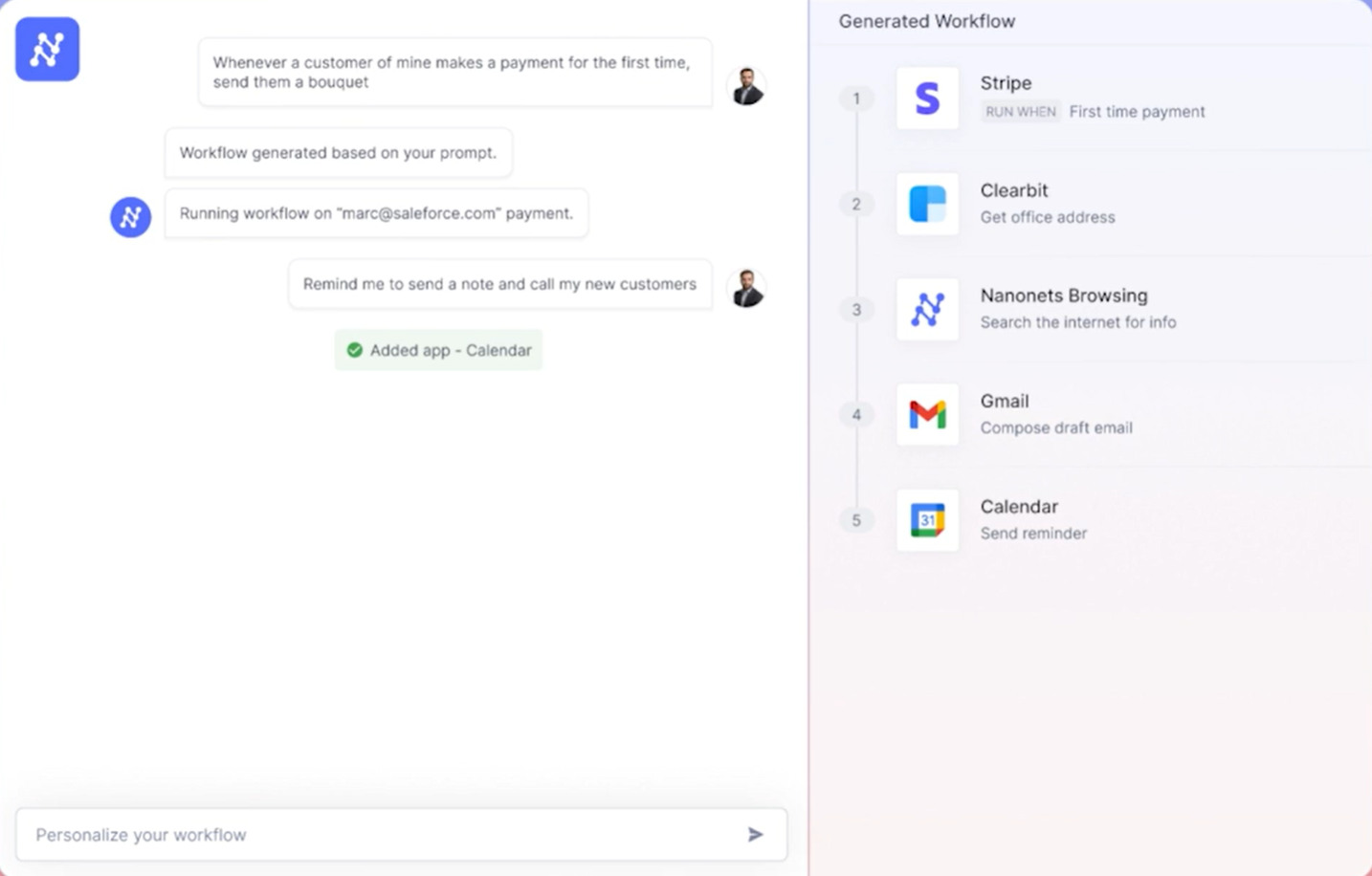

Nanonets is a platform that offers an operationally efficient, AI-driven automated order processing system. The setup is simple and doesn't require any code, making it accessible for businesses of all sizes.

Firstly, let’s understand what Nanonets bring to the table:

The benefits of order processing with Nanonets

| Stage | Before Nanonets | With Nanonets | Nanonets Advantage |

|---|---|---|---|

| Import | Manually sorting through emails and attachments. | Forwards customer emails to capture orders. | Streamlines capture process, saving time and reducing manual work. |

| Extract | Manual data entry with high error risks. | Uses OCR to extract data accurately. | Eliminates manual entry and increases data accuracy. |

| Analyze | Time-consuming manual data review. | Automates data analysis with custom business rules. | Enhances efficiency and handles exceptions intelligently. |

| Push | Manual input into ERP or CRM systems. | Auto-formats and pushes data into systems. | Speeds up data integration and reduces entry errors. |

| Integrate | Complex tool integration. | Seamless sync with business tools. | Simplifies integration, aligning with existing workflows. |

Here's how you can establish automated order processing with Nanonets:

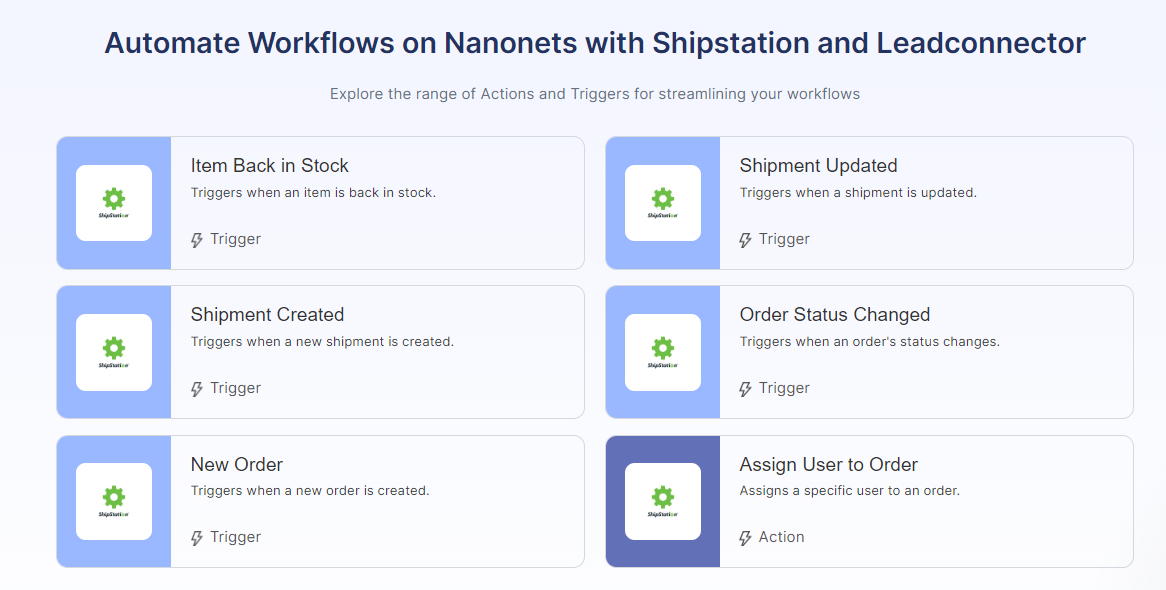

Step 1: Integrate your systems

Whether you collect orders via Gmail, Google Drive, Typeform, or a Webflow-based website or use more complex systems like SAP or Oracle, Nanonets can be seamlessly integrated. You can set up auto-import of orders from your order collection platform to Nanonets through APIs, Zapier integrations, or direct integration.

Step 2: Train your model

Upload a few past orders to train the system. Nanonets employs OCR, ML, and AI technology to understand your order forms and extract data accurately. You can fine-tune and retrain your model with new data to improve accuracy and adapt to changing order formats.

Step 3: Configure your workflow

You can customize your workflow based on your business requirements. Define the sequence of tasks and rules for routing and approvals. Configure triggers for specific events, such as if the extracted data from an order form has discrepancies or if the inventory level is insufficient.

Step 4: Export your data

Once the system has extracted and validated the data from your orders, you can export the data to your preferred destination. Nanonets supports multiple output formats, including JSON, XML, CSV, and direct API calls to other systems. You can automate data export to your inventory management system, CRM, or any other system you use.

Step 5: Monitor and optimize

With built-in analytics, you can monitor the performance of your automated order processing. Track key metrics, identify bottlenecks, and make data-driven decisions to optimize your processes continually. Regularly reviewing and updating your workflows will help you maintain operational efficiency and high customer satisfaction.

Automated order processing best practices

Adopting best practices in automated order processing can steer your business toward remarkable efficiency and customer satisfaction. Implementing these methods ensures your operations run smoothly and adaptively in today’s fast-paced market.

1. Implement end-to-end automation

While partial automation may address specific bottlenecks, it's the end-to-end automation that truly transforms operations. From order receipt to fulfillment, every step can benefit from reduced manual intervention, which in turn minimizes errors, accelerates the order-to-cash cycle, and ultimately improves customer satisfaction.

Checklist for end-to-end automation:

- Automate order receipt and input from all sources.

- Employ automated data extraction and verification.

- Set up auto-routing for approvals and processing.

- Integrate automated shipping and inventory update systems.

- Use system alerts to manage stock levels and avoid backorders proactively.

2. Embrace AI-powered analytics

Leveraging artificial intelligence in analyzing order data can unearth valuable insights that drive more intelligent business decisions. Using AI, you can predict trends, understand customer behaviors, and optimize inventory, which leads to better demand forecasting and reduced stockouts or overstock situations.

Example of AI-powered analytics in action:

- Analyze past order data to predict future demand patterns.

- Implement real-time analytics to adjust inventory levels dynamically.

3. Prioritize customer-centric automation

Incorporating automation focusing on the customer's needs leads to a more personalized and satisfying buying experience. This includes implementing systems that provide timely updates on order status and customized recommendations based on buying history, strengthening customer loyalty, and encouraging repeat business.

Action items for customer-centric automation:

- Introduce chatbots for real-time order tracking and queries.

- Install recommendation engines using AI to personalize up-sell and cross-sell suggestions based on customer profiles and purchase history.

- Use automated feedback mechanisms post-delivery to gather customer insights and improve service.

4. Select the right automation tool for your business

Contextually speaking, the first step in transitioning to automated order processing is choosing a tool conforming to your business requirements. It should be versatile enough to handle different order formats and systems and adaptive enough to accommodate business changes and expansions.

For instance, with Nanonets, you are choosing a tool that offers seamless integration with various operation management systems — be it Gmail or advanced tools like SAP or Oracle. Its machine-learning function allows for the continuous learning of order formats, thereby remaining relevant to evolving business needs.

5. Continuously train your machine-learning model

A common oversight in order processing automation is the "set and forget" mindset. Businesses must continuously feed their machine learning models with new data to improve accuracy and efficiency, adapting to the nuances of their evolving order processing needs.

For example, by utilizing the continuous learning capabilities of Nanonets, businesses can contribute anonymized order data to improve their models. The practical side of this is seen in fewer order processing errors and more nuanced recognition of your specific order formats, which translates to improved customer experiences.

6. Enhance data security and compliance

Automating order processing also means ensuring the data is secure and the system complies with relevant regulations. This is critically important as data breaches or non-compliance can lead to significant financial penalties and loss of customer trust.

Guidelines to bolster security and compliance:

- Ensure automated systems comply with data protection laws like GDPR, HIPAA, etc.

- Conduct periodic audits and risk assessments of automated order processing systems.

- Educate staff on data security best practices in the context of automated systems.

- Implement robust encryption for data at rest and in transit.

7. Streamline returns processing

An efficient returns process is as necessary as the initial order fulfillment. Automated returns processing can significantly enhance customer satisfaction by simplifying the customer's effort to return merchandise and ensuring rapid credit or exchanges.

Steps to automate returns processing effectively:

- Set up self-service portals for hassle-free return initiation by customers.

- Use automated system like ai document sorting, inspecting, and restocking returned items.

- Deploy software to process refunds or process exchanges swiftly.

8. Leverage cloud-based order processing systems

Shifting to a cloud-based order system provides flexibility and scalability, essential for growth. With the cloud, businesses can easily manage order spikes during peak seasons without compromising performance or customer experience.

To reap the maximum benefits:

- Choose a cloud solution with a strong uptime record.

- Ensure the solution can scale up resources during demand surges.

- Opt for providers that offer strong security measures and data protection.

- Look for cloud solutions with integrated analytics for better decision-making.

- Select systems that allow for easy integration with other tools and platforms.

9. Regularly review and optimize workflows

Continuous improvement is critical to maintaining an effective automation strategy. Regularly analyzing and refining automated workflows helps identify and resolve inefficiencies, keeping the system aligned with the changing business landscape.

If you are a Nanonets user, you can set up the following workflows to make the most of the system:

- Automate data entry to QuickBooks.

- Turn Webflow form submissions into order entries.

- Create event triggers in Slack or Microsoft Teams for specific order-processing milestones or issues.

- Use Zapier to connect Nanonets with other apps for extended workflow automation.

- Integrate with CRMs to ensure all customer information is synchronized and up to date.

Maintaining an efficient, automated order processing system isn't just about adopting new technologies; it also involves streamlining existing processes and ensuring staff are well-trained to handle new applications.

By adhering to these steps, businesses can enjoy the myriad benefits of automation and position themselves for success in today's fast-paced market.

Final thoughts

The future of order processing is unmistakably tied to the strategic implementation of automation. Companies that embrace these technological advancements are poised to achieve greater efficiency, accuracy, and customer satisfaction.

As the digital landscape evolves, staying at the forefront of automation will become not just an asset but a necessity for businesses wanting to remain competitive and meet consumer expectations for swift, seamless service.

The key takeaway for any business is clear: Invest in automation, but do so mindfully and continuously evolve it to fit the changing demands of the market and your customers. With a customer-centric approach and a willingness to adapt, your business can transform order processing into a powerful asset for growth.

FAQs

What do you mean by order processing?

Order processing refers to the steps involved in receiving, validating, and fulfilling customer orders. It includes capturing order details, checking inventory, getting approvals, picking and packing items, shipping orders, and finalizing payment. Automating this workflow enhances speed, accuracy, and the overall customer experience.

What are the steps of order processing?

The three core steps in order processing are:

- Order Entry: Capturing order details from the customer via phone, email, e-commerce site, etc.

- Order Fulfillment: Validating order accuracy, reserving inventory, picking and packing items, and organizing shipping.

- Order Finalization: Generating invoices, processing payments, and recording the transaction.

What are the 5 stages of the orders process?

The five critical stages in processing orders are:

- Order Placement: Customer submits order through phone, email, website, etc.

- Order Verification: Validating order details like items, quantities, pricing, and customer info.

- Order Preparation: Reserve inventory, pick and pack items, and select a shipping method.

- Order Dispatch: Generating shipping documents, sending shipments, and notifying customers.

- Order Completion: Receive payment, issue invoices, and record transactions.

What are the elements of order processing?

The main elements of order processing include:

- Order capture

- Data validation

- Inventory checks

- Credit checks

- Approvals

- Picking and packing

- Shipping

- Invoicing

- Payment collection

- Returns handling

Automating these elements streamlines order fulfillment from end to end.